Well, not really. It's a few years ago now, but I ran the Homologation Department at Honda UK for several years and whatever testing was required would have been done.

.... which is 'no crash testing' ....

To head off any criticism of "oh the unsprung weight, the horror", have you ever weighed the rear end of a shaft drive motorcycle?

Ironically, like david,

I had a FJR13, which I weighed on scales

135kg rear, 130kg front.

Heavy bike. That's pretty much what a 20kWh bike will come in at.

Too heavy for my taste, TBH. I sold it because a bike should be 'an occasion' when you wheel it out, not 'a fight with gravity'!

I fear for the future of electric bikes because to get range they either have to have large batteries, which makes them heavy, or rapid charging, which means high voltages which means large batteries which means .... etc..

A 7~8 kWh battery is 160~170kg, which is fine and would get you 100 miles so long as you don't go over 50~60mph.

This is about the ideal, but means a slower world of riding. TBH, for me, I don't mind. Everything is slowed down on the roads, and too easy to get speeding tickets, but it makes motorways a bit of a chore when it gets slower than 60ish, you need to be able to get past trucks, at least.

As soon as you want to go 100 miles at motorway speeds, you need to add more battery, which adds weight, which reduces efficiency, which adds more weight, which reduces efficiency, so you end up with these super heavy electric bikes.

Battery cell's kg/kWh have barely improved in 10 years. The density, L/kWh, has dropped, which is good for cramming batteries into smaller cars, but it is weight that is the bike's problem.

If LiS ever becomes a reality then it will finally make electric bikes 'a real thing'. Until then, with current battery tech, they are either short range/slow urban runabouts or heavy cruisers.

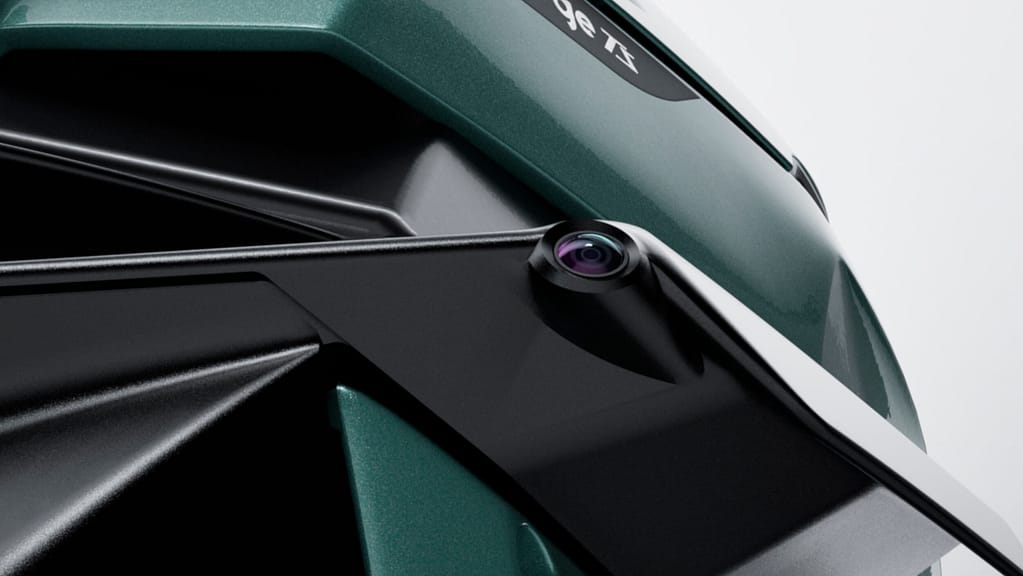

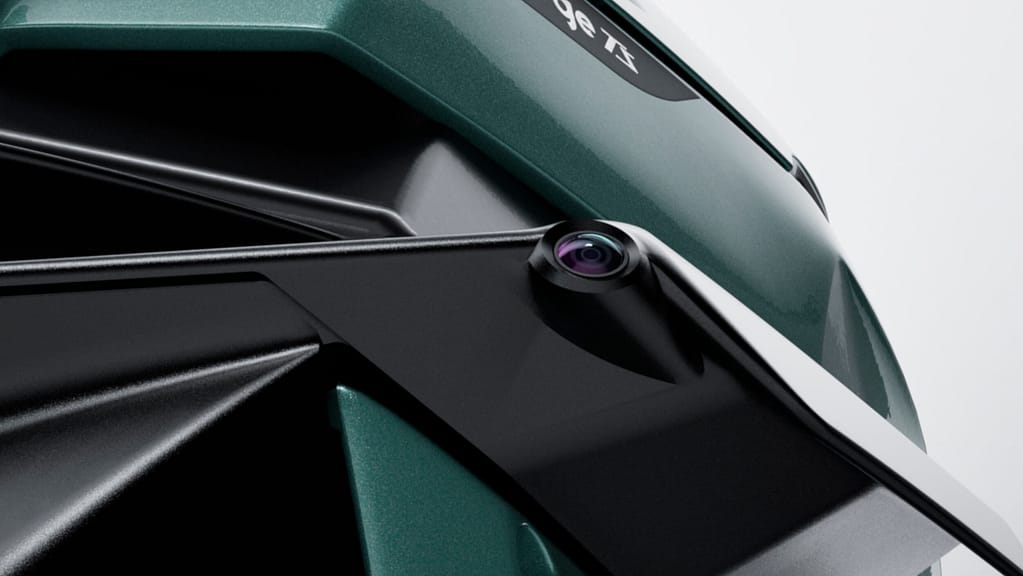

www.vergemotorcycles.com

www.vergemotorcycles.com

![Image]()